Hello guys (and gals) thanks for letting me in here. I live in North Wales in the United Kingdom. I am not far from the English city of Chester (just in case any non-UK people are reading this)

I am building a BMW K100 motorcycle with a 2009 Smart CDI Diesel engine. Forgive me therefore if I ask some stupid questions.

Just to give a few background details in case anyone isnít familiar with whatís needed, the Smart gearbox is not used and an adapter plate is made to go between the motorcycle gearbox (which is shaft drive) and the rear face of the Smart engine.

The engine sit bolt upright and the bottom of the sump is cut off to make it flat and give ground clearance.

The exhaust manifold and turbo assembly is turned upside down using an adapter plate. The turbo oil drain goes into the dipstick tube and the dipstick is no longer needed. There is an oil sight glass in the side of the sump.

The Smart clutch is not used and the motorcycle clutch assembly is mounted onto the Smart flywheel. The Smart flywheel no longer becomes a friction surface. This is necessary because of the rather odd way which the motorcycle gearbox (in this case) works having a very short splined input shaft and with the clutch operating pushrod going through the centre of that input shaft rather than around the periphery using a conventional release bearing. BMW did their own thing with this motorcycle!

Here is the clutch carrier installed on Smart flywheel

So, moving swiftly on, I have some questions about the throttle arrangement for the diesel motor and other things

The engine I have is incomplete and Iím trying to ascertain what is missing. I know the electronics are going to be a nightmare but I will buy a Specialist Components ECU and wiring diagram which gets rid of all the extra non-required connections such as the gearbox, EGR, particulate filter et cetera.

All the throttle assemblies photographs I have seen on the Internet show them attached with 4 bolts.

I have seen a photograph of the plastic manifold on its own with a rubber adapter on the end but nothing for 4 bolts.

http://www.ebay.co.uk/itm/2014-SMART...0AAOSweW5VGXO0

This what I have

I have searched on the Internet in vain for a parts diagram

My Smart Diesel engine is missing complete throttle assembly. I have nothing other than the plastic composite inlet manifold. Can somebody tell me (part numbers and photograph/diagram/illustration will be fantastic) what goes between the plastic inlet manifold and the pipe from the turbo?

It seems that as soon as you put the words Smart Car in front of whatever youíre looking to buy, the price trebles! Parts for normal Mercedes seem to be much cheaper.

Therefore, is there another throttle body from something else which could be substituted? I see that some people running petrol cars have replaced them and I happened to read a thread a short while ago where someone had used a Corsa unit but that was a petrol engine. Any suggestions in that respect be really useful.

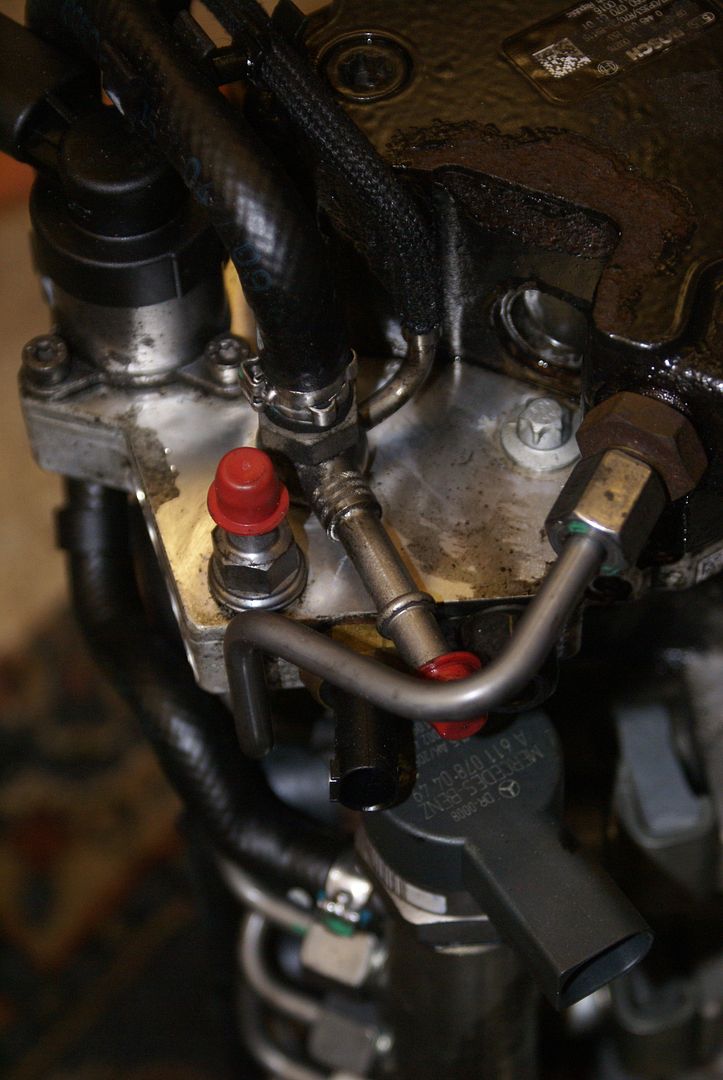

Here is a photograph of the pump. Is this the only pump there is? Being fitted in a motorcycle, the tank would normally gravity feed to the fuel pump. Does everyone think that will be sufficient or should I put another electric pump in to feed the diesel pump? I guess the short pipe (with the little Red Hat) is the feed and the long pipe with a little Red Hat is the return. Is there anything magic about the feed and return or does the return simply empty back into the tank any excess pressure? Does anyone know how much pressure should be in there? The motorcycle had fuel injection and therefore there is a pump inside it which could be used but I think it would need a pressure regulator because it was originally to drive petrol injection.

Now for the really stupid questions. These cars have electronic pedal. Is there no mechanical connection between the throttle body and the foot pedal or is there some kind of box somewhere (not the ECU) which Iím going to need?

What does this zinc plated bracket do? It looks like it used to have a cable in it.

Itís going in a motorcycle and therefore there is no need (lots of fresh air around) for an intercooler. Also, the EGR is binned and the new Electronics takes care of that.

I think this is the old EGR take off in the zorst manifold which is going to be blanked. Can someone please confirm?

Finally, I know that the turbo runs on plain bearings. I am aware of the necessity for good oil. How much play (if any) should be discernible in the turbo shaft?

Yes, I know itís a big and ambitious project but it has been done before and I know that it can be done and hence, it will be done. I am seriously committed to this and have already set aside the funds and got the motorbike and the Smart engine of course.

The clutch is already machined into the flywheel cannot be assembled totally until the gearbox is lined up. I will get the mounting plates laser cut next week.

Thanks for replies everyone.

Regards

James

Comment