Exactly that. People have been bought up in a throw-away society as it's what makes companies money. They sensible option is, where practicable, perform a repair/fix. It saves money and broadens experience.

Announcement

Collapse

No announcement yet.

450 outside temperature sensor

Collapse

X

-

The thermistor I fitted is manufactured by Epcos. Resistance at +25C is 3000 Ohm. Beta value 3988K.

Data sheet added below. RS stock number is 528-8508. Available from RS Components for a reasonable fee, see previous posts.

Of course transport will add to the repair cost but I also have a solution for that:

Just get yourself a bus pass and enjoy free travel with free wireless broadband.

Outside temperature sensor A0005428418 opened out and new thermistor fitted. Thermistor is coated in heat conductive grease.

The usual precautions must be implemented when soldering in a new thermistor and a successful repair is only possible if one possesses the required skills.Attached FilesLast edited by tolsen; 08-02-16, 12:45 PM.

Comment

-

I did initially wonder how much cheaper this new thermistor was going to be when I saw that it had to be collected from RS in Abz - until I saw the 'free bus' post.Originally posted by tolsen View Post

Of course transport will add to the repair cost but I also have a solution for that:

.

It's the transportation costs that are an issue in the UK and everyone is affected differently. In my case to collect from RS in Abz entails a 120 mile trip taking at least three to four hours. By contrast, the smart dealership will deliver to my door for no additional charge.

Comment

-

A few winters will pass before I get mine!Originally posted by tolsen View PostI do appreciate for some it might be too late by the time they get their bus pass.

No doubt, and if the carriage costs are within reason (as someone already remarked, some delivery charges would pay for a pallet delivery) and it goes through the letter box (a thermistor, I know, will) without the need for a signature (or wait around for it to arrive, just stuck there) then ordering from the 'net is a boon. No need for a thermistor here though - my Pure isn't enabled for it. The colour of the road is more what concerns me.Originally posted by tolsen View PostEbay is then the answer. There are lots of suitable 3k NTC thermistors there if you only take time to look.

Any idea (yes I'm still on this) why the number of splines differ (24 vs 33) from outer and inner ends of a smart driveshaft? They see the same torque. Why different? (Answer me that and I'll tell you why the bearings inside a 450 gearbox are the sealed type).

Comment

-

Inboard spline is stronger than outboard due to the larger major spline diameter (major diameter of inboard 33 teeth spline is 27 mm and major diameter of outboard 24 teeth spline is 25.75 mm). Both splines are stronger than the adjacent shaft.Originally posted by Thrumbleux View PostAny idea (yes I'm still on this) why the number of splines differ (24 vs 33) from outer and inner ends of a smart driveshaft? They see the same torque. Why different? (Answer me that and I'll tell you why the bearings inside a 450 gearbox are the sealed type).

Why different? Most likely to do with what machine tools are available at the manufacturing plants. Rear bearing cannot accommodate a larger diameter spline without increasing bearing overall diameter. This would of course also increase unsprung mass.

Having different splines inboard and outboard on driveshafts is normal.

Now tell me why some bearings inside transmission are sealed.

Comment

-

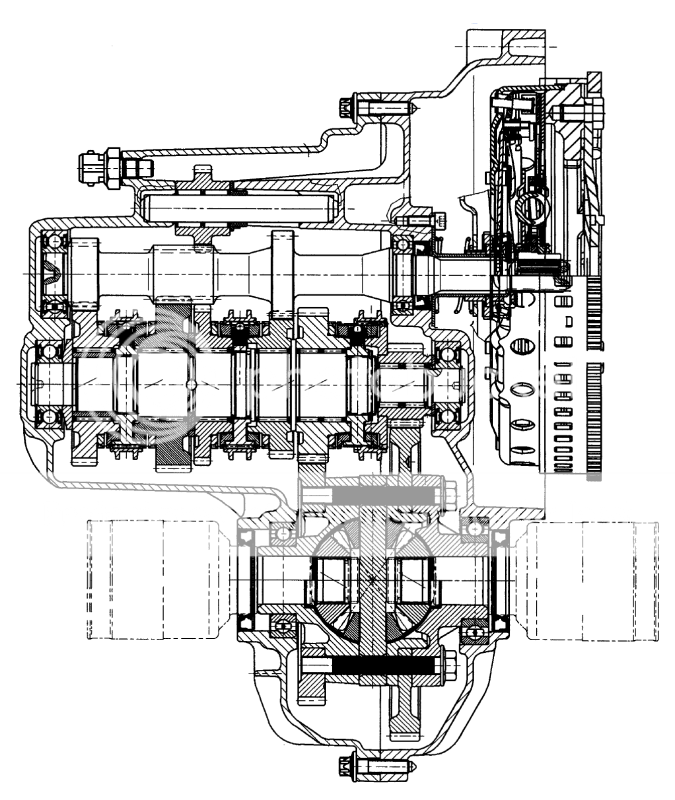

Here is a video showing a 450 transmission opened out:

One can clearly sea that only some bearings are sealed while others not. The theory that sealed bearings were fitted to safeguard against bearing failure due to small metal particles from initial transmission break in does therefore not hold water.

It is the sealed bearings that fail in this transmission. Failure mode is lack of lubrication when the grease inside the sealed bearings dries out.

6304 2RS bearing with rubber seal removed taken from cluster gear. Balls are rather pitted.

Comment

-

It was reading that thread (looking for more info on splines) that I came across the sealed bearing conundrum. The reason (I think) will be so that they can be packed with grease fortified with anti-wear additives to compensate for the low viscosity ATF. To raise the load bearing capacity of an oil with typical ATF viscosity would entail loading it with anti-wear additives that would attack and pit the yellow metal synchromesh cones. Unfortunately, sealed bearings rarely contain grease of any significant quality. Why would they? Bearing manufacturers make money selling replacement bearings - not by making them last longer.

Given that chunkier inner splines is commonplace, perhaps it's preferred that the outer fails if there's going to be a failure. Easier/cheaper fixed.

Comment

-

I've seen transmissions where all bearings are sealed. In that case the seals will prevent damage caused by tiny metal particles released during transmission break in. In our transmission all differential bearings are unsealed. In gear box itself, bearing nearest to clutch on input shaft is unsealed while bearing at other end of input shaft is sealed. Both end bearings on cluster gear are sealed.

The bearings that see the highest loading are those that are sealed and lubricated with grease. Using the online SKF bearing calculator one can quickly calculate bearing life. Have just done that and concluded bearing life drops dramatically as soon as contaminants are introduced. Longest calculated bearing life was with sealed grease lubed bearings and open bearings lubed with clean oil. Oil viscosity had no effect on bearing life. Clean oil and grease gave identical bearing life.

My conclusion is that Getrag design engineers had done bearing life calculations and found too short life for three high loaded bearings. A simple solution was then to specify double sealed grease lubricated bearings for these to ensure a reasonable overall expected life of the transmission. Regrettably, they did not take into consideration that the grease dries out which is why this transmission fails. The good news is that these bearings are rather cheap about 5 Pounds each and that they are very easy to replace.

Of course, changing transmission oil will drain out most of the tiny metal particles released during break in period, resulting in increased life of the open bearings inside transmission. Because the bearings that fail are sealed, renewing the transmission oil will however result in no overall increase in transmission life. That is why Smart does not specify any oil change interval for the 450 transmission. Renewing transmission oil is therefore just a pointless exercise

Comment

-

Film strength and thus its ability to be breached and permitting metal to metal contact is very much viscosity dependent. It is during that scenario that anti-wear additives are required to prevent damage. Anti-wear additives that attack yellow metals.Originally posted by tolsen View PostOil viscosity had no effect on bearing life.

Unlikely there is sufficient heat for the grease to dry out and for that to occur the oil has to migrate somewhere - meaning it would have to pass the seals. More likely the anti-wear additives were just ground into submission. They don't last forever - which is why, generally speaking, we periodically re-grease a bearing (when possible). The lower the quality the oil within the grease the more the film is breached, the sooner the anti-wear additives become depleted.Originally posted by tolsen View PostRegrettably, they did not take into consideration that the grease dries out which is why this transmission fails.

Comment

-

Oil viscosity does not matter much for deep race bearings. The balls do not slide but roll. Go and run the calculations and you will see for yourself.Originally posted by Thrumbleux View PostFilm strength and thus its ability to be breached and permitting metal to metal contact is very much viscosity dependent. It is during that scenario that anti-wear additives are required to prevent damage. Anti-wear additives that attack yellow metals.

Have a closer look at photo of bearing posted previously. It is completely dry. No grease what so ever.Originally posted by Thrumbleux View PostUnlikely there is sufficient heat for the grease to dry out and for that to occur the oil has to migrate somewhere - meaning it would have to pass the seals. More likely the anti-wear additives were just ground into submission. They don't last forever - which is why, generally speaking, we periodically re-grease a bearing (when possible). The lower the quality the oil within the grease the more the film is breached, the sooner the anti-wear additives become depleted.

Comment

-

Roll they may, but not without friction or no lubricant would be required. The oil is to keep the metals apart - the film strength all important.Originally posted by tolsen View PostOil viscosity does not matter much for deep race bearings. The balls do not slide but roll. Go and run the calculations and you will see for yourself.

Failed bearing. Too late to analyse running conditions prior. The heat build up within a failing bearing will destroy any lubricant.Originally posted by tolsen View PostHave a closer look at photo of bearing posted previously. It is completely dry. No grease what so ever.

Comment

-

Are these splines manufactured to an industry standard? All I can find is an industry standard for PTOs - with very course splines.Originally posted by tolsen View PostInboard spline is stronger than outboard due to the larger major spline diameter (major diameter of inboard 33 teeth spline is 27 mm and major diameter of outboard 24 teeth spline is 25.75 mm). ]

Comment

-

Ad Widget

Collapse

Comment